The last few sections of the work Vymanika Shastra deal with four types of kritaka vimanas, Shakuna vimana in the lead.

Twenty-five vimanas of this category of the current Yuga are stated as follows:

Shakuna

Sundara

Rukma

Mandala

Vakratunda

Bhadraka

Ruchaka

Virajaka

Bhaskara

ajaavarta

powshkala

Viranchika

Nandaka

Kumada

Mandara

Hamsa

Shukaasya

Sowmyaka

Krownchaka

Padmaka

Symhika

Panchabana

Owryaayana

Pushkara

Kodanda

The text Manibhadrakarika, quoting sage Gowtama as also Shounaka sootra indicates the same number of vimanas in the same order. This perhaps reflects that both the sages had the same origin of study. Prescribing specific alloys for the structure of Kritaka variety, the text Kriyasara dictates use of Raja-loha. This prescription is echoed by Vishwambhara also. The process of manufacture of Raja-loha is discussed in brief. Here all the three Ooshmaapa core-metals figure.

Soma, Soundala and Mourthweeka in proportion of 3:8:2 mixed with borax and melted 272 ° and churned form this alloy.

Observations:

-

While Shakuna, Sundara and Rukma appear in the list, Tripura vimana discussed in the work is conspicuously missing. In fact, Tripura does not feature among vimanas of Tretha and Dwapara categories as well.

-

The core metals of heat resistant variety discussed under the Lohadhikaranam form the alloying components of Raja-loha. This indicates continuity from the said chapter and the current one.

-

Lohadhikaranam dealt with core metals of specific thermal resistant variety. Raja-loha among them is an exclusive alloy developed for very specific properties.

Shakuna Vimana:

This vimana contains twenty-eight parts. They are Peetha or Floorboard; hollow mast; three wheeled keelakaas; four heaters; air suction-pipe; water jacket; oil tank; air heater; heater; steam boiler; viduyut yantra or electric generator; air propelling yantra; vaatapa yantra or air suction pipe; dikpradarshana dwaja; shakuna yantra; two-wings; tail portion; owshnyaka yantra or engine; kiranaakarshana mani.

Constructional aspects of the vimana are given too briefly and also without clarity. However, from the English translation (literal and frequently sprinkled with modern terminology) we have made an effort to analyze. Floorboard is a sheet-metal structure made of Raja-loha options have been offered to make the shape circular, rectangular or cradle shaped. Weight of the Peeta or Base is one hundredth of the total weight of the plane. Width of the peeta is half the height of the mast. Hollow mast is to be erected by suitable joinery at the center of the peeta.

Lallacharya quoting yantra-kalpataru prescribing only Haatakasya metal for the mast or stambha specially describes hollow mast. In this particular case a quadrangular base with two ends converging into triangular form has been opted. Hollow mast or Naala stambha is a three tiered-construction inside and outside diameter reducing with each tier upwards. Wheels provided on the length of the Hollowmast are not meant for movement of the vimana. From the description available two outer fixed wheels and the central rotating wheels, some kind of a compressor / turbine arrangement seems to be under discussion to obtain higher pressure and velocity.

Window-Dome provided at the top of the vimana accommodates the sun crystals crowning the dome. Sun crystal is big in size. In the three vertical tiers of vimana, the first tier rests on the peetha. They are separated by thick floorboard. First floor houses four heat engines at the corners. Supporting pillars in the ground floor accommodates passenger cabin. Second floor or tier accommodates angayantras.

Below the ground floor a cellar houses some yantras, four air compressors are provided and around the bottom of Hollow-mast. Air compressors are supposed to be driven by steam power.

The arrangement described for the wing is interesting. The wings are made of a number of feather-like structure stacked one over the other and move around a common pivot. They can open out or close as seen in a feeler-gauge. The wing will also flap along hinged joints to generate lift.

A separate tail plane to facilitate elevation or take-off is provided. As per the description the heat engine drives the propeller to produce usual aircrew action. Controlling of wing feathers and tail units is through control cables originating from the cockpit.

Ignition of the oil (fuel) seems to be by electrical means. For storing compressed air leather bellows have been suggested.

Observations:

Preparation of Hatakasya alloy has been covered earlier in this report.

Construction of the structure and a hollow mast hints at attempts to achieve streamlining.

Units of measurement like Vitista needs to be verified and established conclusively.

Three sets of wheels along the length of the hallow mast, hint at their being power developing source. Wheels for the movement of the vimana on ground are separate.

Use of sun crystal is obviously for solar energy extraction.

Use of steam power to drive air compressor seems to be strange since steam generation during flying is itself strange.

Possibly Shakuna is one of the early variants of Kritaka type, deriving its name from the basic definition of bird. Hence the arrangement of flapping and spreading wing and tail construction feature.

In essence Shakuna is a rudimentary type with aircrew arrangement.

Sundara vimana:

Eight constituent parts are:

Peetha or ground plate Smoke chimney

Five gas engine Bhujya metal pipe

Wind blower Electricity generator

Four phased heater Outer cover

Peetha or ground plate of Raja-loha with options to have square or round shape. In the centre of the peetha Dhoomaprasaran Naala or pipe is provided. Hollow mast is a tall cylindrical member with provision to store gas energy at the bottom portion. Water vessels, oil tanks are housed at the centre. At its foot electricity is stored in a container.

Oil container will have three oils: Dhoomanjana oil, Shukatundalika oil (eggplant oil) and Kulaki or Red arsenic oil in the ratio of 12:20:19. Ignition of the oil mixture is by electrical means. Distribution of gaseous products seems to be through a special arrangement ensuring even spread of gases. Dhoomodgama yantra is meant to eject gaseous mass with speed. In constructing this only Dhooma garbha loha with composition of Himasamvardhaka, Soma and Soundala metals have been specified. Control of high-energy gaseous products is through revolving wheels (possibly to operate valves). Description indicates a hydraulic accumulator type of arrangement for storing gaseous product. Ignition of oil is achieved by combined process of electrical energy and friction.

Actual thrust is obtained by passing the high-energy product through a number of Sundalas or Jet nozzles. This obviously seems to be based on reaction principle. Manufacturing process of Sundala (made out of special metal-impregnated fabric, flexible, heat-resistant) as given by Lallacharya is explained in brief. These sundalas or naalas are kept rolled-up over revolving drum while not in use. They are unrolled and kept taut while in use. The gaseous products get discharged through a number of them in jets producing thrust.

Generation of electric power has also been briefly covered. The text talks of 32 types of machines to produce electrical power. Different methods broadly stated are friction, by thermal process, by waterfall, by combination of all these and also by solar rays. This technology is ascribed to sage Agastya in his work Shaktitantra. Electrical power production is described using four vessels located in four directions and a central vessel. Several types of acids, dravas are used in each vessel. Crystals or Manis such as Vidyutgama, Jyotirmukha play a key role.

Extensively treated lion’s skin and deer’s skin (possibly for their high insulation properties) figure in the process. Central vessel forms the accumulator of electricity generated. Anshupa Mani or Solar rays absorbing crystals is the main medium that absorbs heat that gets converted to electricity through a process not clearly described. The process of storing electricity by use of mercury has also been brought in. Stored electricity is conducted to all parts of the vimana through insulated cables for operating various services.

Vataprasaran yantra is described as one to generate the main Udgama Shakti or lifting force. This yantra comprises of twelve parts, including Naala-Stambha, valves regulating inlet / outlet for fresh, compressed air, exhaust, air guides, vanes. The system includes an air compressor. The description hints at using compressed air jet to obtain thrust. Further description mentions that compressed air conducted through Naala sthambha and energy product by Dhoomodgama yantra through the inside of the main mast or Bruhad sthambha. They confluence at the end and go out through sundalas with high velocity, effecting jet propulsion.

As stated for Shakuna vimana, Raja-loha is used for structure and covering of this vimana also. Chaturmukha or Oushnya yantra is the main heat engine. Comprising of 18 parts this includes, Peetha, Smoke accumulator, Oven, Water container, Valve controls, smoke opening, Regulatory valve, heat indicator (temperature), Time clock, Speedometer, Sound-transmitting instrument, Anthardhanda Ghata, air bellows, Long sundala pipes, Copper pipes etc. Sundala used as jet nozzles to obtain thrust are also used for vertical and aft movements and directional control of the craft. Computation of speed claimed to be achieved needs a re-look. The thrust from each contributing source seems to have been added up. Retranslation of many verses in this chapter may help in better understanding.

Observations:

-

Use of specific types of oils suggests that high-energy potent fuel be under discussion.

-

Some error is noticed in the direction of movement of the craft vis-à-vis jet stream from sundala nozzles. Applying the principle of reaction the movement of the craft should be in the direction opposite to the thrust line. Possibly this aspect is dealt by Swami Dayananda Saraswati in his Rigbhashya Bhoomika. Incidentally this is quoted in the report of I.I.Sc Bangalore also.

-

Very importantly solar energy employment for producing electricity is a unique feature. Probably this technique was not heard of even by the middle of 20th century.

-

Use of sundalas, as jet nozzles are again interesting. Operating each sundala independently and varying mass-flow and velocity of jet separately, multiple degree of craft control should be available.

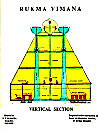

Rukma vimana:

The description of this vimana is too brief to comprehend the principles of working. Rukma meaning gold, the vimana has been so named because of its appearance of golden colour. Impregnating gold colour on Raja-loha precedes fabrication of structural part of vimana. Yantra-Bindu and Varna Sarvaswa explain the colouring process. From the manner described it is not a plating process.

Peetha is stated to be tortoise shaped of length 1000 ft. This however is too long and needs translational, interpretational verification as well as equating units of measurements of length. The other parts are Ayaschakra pinda and Batimikaa sthambha. Description of flying lacks clarity. However, utilization of electrical energy to operate Electro-Mechanical arrangement to enable vimana to lift off and accelerate is hinted. A speed of 105 kroshas or 250 Mph. per ghatika is stated. Directional control as suggested by Lallacharya is through conventional rudder system provided at the base and articulated through crescent shaped plate by means of push pull rods.

Observations:

-

Pushpaka vimana of epic Ramayana is also described to be golden colour and delightful looking. Aesthetic sense of the scientists to cater for the needs of the Royale manifest here. Gold colour imparted to Raja-loha is before the alloy is used in structural part. In fact it is built in the alloying process itself to make it an integral part of the metal.

-

We note that the earlier two vimanas discussed did not mention of gold colouring.

-

Rukma is stated to reach speed up to 250 miles in 24 minutes, a speed of 725 miles per hour.

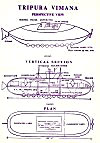

Tripura vimana:

Tripura is the last of the representative vimanas discussed in the text. It has two unique features. It is a three-in-one craft and also a solar powered vehicle. Tripura means three storey or tiers. This concept is brought in the form of a three-tier construction. The first tier is for operation on land, the second one for operation on water and inside water and the third for flying in air. As an integral unit of three tiers the craft is stated to be a flying machine. Differential use of first and second tiers independently for movement on land and water is stated to be possible.

In contrast with the other three vimanas this is to be made of mica (first floor) and Thrinetra loha (second and third floor). The arrangement talks of wheels provided underneath peetha for locomotion on land through electric motor. The wheels are retracted from the ground before vehicle moves into water in amphibian mode. During movement on water boats provided on the deck possibly to act as buoys.

Detailed manufacturing process of obtaining particular type of mica has been dealt at length. Layout details of the first floor include provisions for aisle, cabins for crew and passengers and storage enclosure. Covering of the first floor is by water / air proof fabric, easy to install and dismantle.

Second floor is proportionately smaller than the first. Electric power is provided to second floor as well. When the second floor gets into water the open hatches of the wheel will be covered by special milk-cloth having full water proof property. Supply of air to the second floor is ensured through ducts made of milk cloth. This air under pressure is meant for comfort of personnel in first and second floors.

For protection, safety and comfort of crew and passengers three separate yantras are provided viz., one to protect against stormy winds, the second against solar-blaze and the third against rainstorm. Construction of the third floor is similar except that it is proportionately smaller. The special feature in the third floor is that it houses electric generator. The cabin for this is to be made of Somaka-loha.

The procedure for extracting electric power from solar rays has been mentioned. Vessels and tubes made of Anshupa glass of a specified variety and some electricity generating crystals participate in the process. Anshupa and Sanjeeraka crystals play the primary function. Purpose and function of Ganapa yantra discussed in the text needs separate study with suitable interpretation.

Observations:

-

Three-in-one concept includes amphibian and under water modes of the vehicle as well.

-

Use of solar energy for powering an aircraft is a unique phenomenon, heard for the first time in the aviation technology.

-

To highlight the features of Thrinetra-loha, it is flame proof, unbreakable, waterproof and above all, weightless. It has the Shane of peacock feather.

General Remarks on Vimanas diagrams and drawings:

Inclusion of diagrams and drawings was an add on activity by Sri. Shastriji from 1918 – 1923 AD. This was done through a local draughtsman under the pandit’s guidance. It is difficult to accept that this process also was under the divine influence. It appears that in projecting the contents of the work through pictures and drawings their own interpretations seem to have influenced. Possibly this has corrupted narration to some extent. We are therefore not inclined to accept the drawings till further study. It is learnt that attempts are under way to build a prototype of one of these vimanas by a researcher in Hyderabad.

No comments:

Post a Comment